WORKSHOPS AND TECHNOLOGIES

DESIGN DEPARTMENT

SCRAP WORKSHOP

CASTING WORKSHOP

FORGING WORKSHOP

SPECIAL EQUIPMENT

MECHANICAL ENGINEERING

SCRAP WORKSHOP

Aerorecycling International is Datum Tree's partner in the scope of the supply of shavings for the production of specialty alloys of specialty steels. Aerorecycling International has a long standing contractual relationship with ITP Aero Spain (now RR https://www.rolls-royce.com/) and has its own shavings separation equipment on their premises.

A large volume of Inconel 718 is always in stock in the form of shavings (from 400 tons monthly).

Also always available titanium scrap up to 60 tons monthly.

Scrap of heat resistant alloys up to 20 tons.

A large volume of Inconel 718 is always in stock in the form of shavings (from 400 tons monthly).

Also always available titanium scrap up to 60 tons monthly.

Scrap of heat resistant alloys up to 20 tons.

1 - High Nickel and Cobalt grade

2 - Stainless Steel

3 - Titanium Scrap

3 - Aluminium Scrap

Inconel 718

Inconel 625

Invar 36

Mar M247

Inconel 625

Invar 36

Mar M247

F316

F304

F51

F53

430

F304

F51

F53

430

7000 series

6000 series

5000 series

1000 series

6000 series

5000 series

1000 series

-

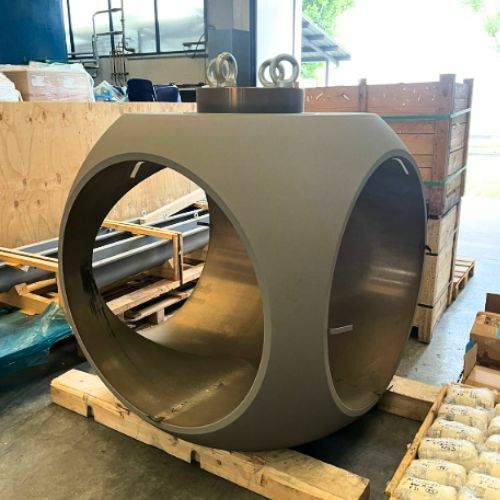

CASTING & MACHINING WORKSHOP

EQUIPMENT:

- Trevisan DS-600 Lathe

- VALMET 1600 x 3000 Lathe

- LAUKO 1100 x 3000 Lathe

- VEMAC 1700 x 2500 Lathe

- Milling machine 5g 36 in.

- Induction furnaces. 5 pcs. simultaneous melting volume of 8 tons of steel

- Welding equipment GTAW

- Cranes with lifting capacity up to 40 tons

- Laboratory

- Trevisan DS-600 Lathe

- VALMET 1600 x 3000 Lathe

- LAUKO 1100 x 3000 Lathe

- VEMAC 1700 x 2500 Lathe

- Milling machine 5g 36 in.

- Induction furnaces. 5 pcs. simultaneous melting volume of 8 tons of steel

- Welding equipment GTAW

- Cranes with lifting capacity up to 40 tons

- Laboratory

TECHNICAL CAPABILITIES:

-Mechanical shop: allows to produce any machining of spherical and conical surfaces, to provide high-precision 3-, 4- and 5-axis machining of parts, to reduce production time and practically eliminate the influence of "human factor».

-Melting of special steel grades according to EN and GOST, as well as special orders.

-Pipes. Pipes production by centrifugal casting up to 3 m in length.

-Melting of balls by centrifugal casting up to 36 inches (ball valves)

-Rings up to 1500 mm. Manufacturing method: Centrifugal casting. Forged. Rolled.

-Manufacture of any parts for shut-off valves.

-Manufacturing of various parts by stamping method

-Sputtering of tungsten carbide and chromium carbide

-Bimetal

-Mechanical shop: allows to produce any machining of spherical and conical surfaces, to provide high-precision 3-, 4- and 5-axis machining of parts, to reduce production time and practically eliminate the influence of "human factor».

-Melting of special steel grades according to EN and GOST, as well as special orders.

-Pipes. Pipes production by centrifugal casting up to 3 m in length.

-Melting of balls by centrifugal casting up to 36 inches (ball valves)

-Rings up to 1500 mm. Manufacturing method: Centrifugal casting. Forged. Rolled.

-Manufacture of any parts for shut-off valves.

-Manufacturing of various parts by stamping method

-Sputtering of tungsten carbide and chromium carbide

-Bimetal

FORGING WORKSHOP

Certificates:

ISO 9001,

ASTM A991,

API RP 6HT,

API SPEC 6A /

ISO 10423, NORSOK M-650 Annex B & AMS 2750

ISO 9001,

ASTM A991,

API RP 6HT,

API SPEC 6A /

ISO 10423, NORSOK M-650 Annex B & AMS 2750

DATUM TREE's services include roughing and finishing to drawings or customer requirements, which are performed in an in-house shop equipped with parallel and vertical lathes and milling machines. In addition, our deep drilling machines allow us to make precision deep holes in tubular plates used in heat exchangers, blades and turbines.

We also partner with a number of external workshops to meet production needs and provide our customers with extremely precise and sophisticated machining and weld surfacing services.

We also partner with a number of external workshops to meet production needs and provide our customers with extremely precise and sophisticated machining and weld surfacing services.

Frequently ordered forged products:

-Rings

-Disks

-Pipe boards

-Flanges, nozzles

-Self-consolidating flange

-Pile, drill pipe

-Shafts

-Rings

-Disks

-Pipe boards

-Flanges, nozzles

-Self-consolidating flange

-Pile, drill pipe

-Shafts

SHAFTS

RINGS

DISKS, COVERS, PLUGS

SPECIAL OPEN DIE FORGING SHAPES

carbon steel and low-alloy steel:

max diameter: 3650mm

max weight: 35000

max diameter: 3650mm

max weight: 35000

Superduplex, high alloy steel: max diameter: 3650mm

max weight: 15000 kg

max weight: 15000 kg

stainless steel and Duplex:

max diameter: 3650mm

max weight: 15000 kg

max diameter: 3650mm

max weight: 15000 kg

carbon steel and low-alloy steel:

max diameter: 4500mm

max weight: 20000kg

max diameter: 4500mm

max weight: 20000kg

Superduplex, high alloy steel: max diameter: 4500mm

max weight: 20000 kg

max weight: 20000 kg

stainless steel and Duplex:

max diameter: 4500mm

max weight: 20000 kg

max diameter: 4500mm

max weight: 20000 kg

carbon steel and low-alloy steel:

max diameter: 1500mm

max weight: 35000

max diameter: 1500mm

max weight: 35000

Superduplex, high alloy steel: max diameter: 1500mm

max weight: 35000 kg

max weight: 35000 kg

stainless steel and Duplex:

max diameter: 1500mm

max weight: 6000 kg

max diameter: 1500mm

max weight: 6000 kg

carbon steel and low-alloy steel:

max weight: 35000

max weight: 35000

Superduplex, high alloy steel:

max weight: 15000 kg

max weight: 15000 kg

stainless steel and Duplex:

max weight: 15000 kg

max weight: 15000 kg

EQUIPMENT AND

TECHNICAL CAPABILITIES

TECHNICAL CAPABILITIES

Heat treatment is the key process that guarantees the structural homogeneity and mechanical properties of each forged product.

EQUIPMENT:

2 chamber furnaces

* H1: 5 x 6 m and height 2,5 m

* H2: 2.5 x 6 meters and 2.5 meters high. - Hardening tank: stirred bath with a volume of 310,000 liters.

- Weight capacity: up to 50 tons

- Temperature: up to 1,200 oC

- Cooling methods: Quiet air, forced air, water quenching and polymer quenching.

- Available treatments: Normalization, hardening, tempering, annealing, solution annealing, aging, stress relief.

- Max. Transfer time: 60 seconds (fully automated system)

EQUIPMENT:

2 chamber furnaces

* H1: 5 x 6 m and height 2,5 m

* H2: 2.5 x 6 meters and 2.5 meters high. - Hardening tank: stirred bath with a volume of 310,000 liters.

- Weight capacity: up to 50 tons

- Temperature: up to 1,200 oC

- Cooling methods: Quiet air, forced air, water quenching and polymer quenching.

- Available treatments: Normalization, hardening, tempering, annealing, solution annealing, aging, stress relief.

- Max. Transfer time: 60 seconds (fully automated system)

HEAT TREATMENT

- The workshop was built in 2014

- Building area: 2.600 m2

- Height: 15 m

- New equipment for medium and large products

- 5 cranes

* 1 crane with lifting capacity up to 63 tons

* 1 crane with lifting capacity up to 40 tons

* 3 cranes with lifting capacity up to 5 tons

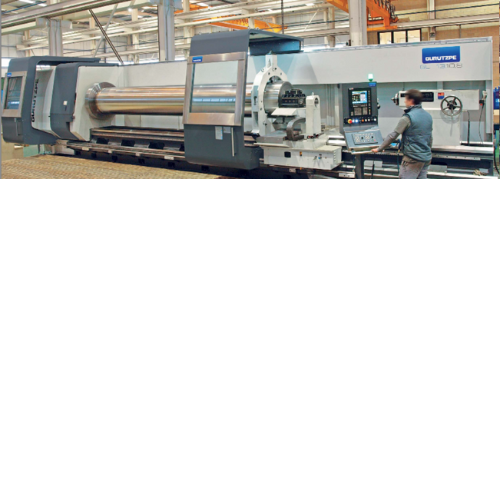

PARALLEL LATHES:

- Max. Displacement above the bed (mm) 2900

- Max. Movement on cross slides (mm) 2,000

- Max. Distance between centers (mm) 8000

- Max. Weight between centers (kg) 40000

VERTICAL TURNING MACHINES:

- Max. Diameter (mm) 3300

- Max. Height (mm) 2,000

MILLING MACHINES:

- Table (mm) 4000*12000

- X shaft stroke (mm) 12000

- Stroke of shaft Y (mm) 3000

- Stroke of shaft Z (mm) 1800 DRILLING STANKS:

- Max. depth (mm) 450 Deep hole drilling machines with internal high-pressure cooling

- Building area: 2.600 m2

- Height: 15 m

- New equipment for medium and large products

- 5 cranes

* 1 crane with lifting capacity up to 63 tons

* 1 crane with lifting capacity up to 40 tons

* 3 cranes with lifting capacity up to 5 tons

PARALLEL LATHES:

- Max. Displacement above the bed (mm) 2900

- Max. Movement on cross slides (mm) 2,000

- Max. Distance between centers (mm) 8000

- Max. Weight between centers (kg) 40000

VERTICAL TURNING MACHINES:

- Max. Diameter (mm) 3300

- Max. Height (mm) 2,000

MILLING MACHINES:

- Table (mm) 4000*12000

- X shaft stroke (mm) 12000

- Stroke of shaft Y (mm) 3000

- Stroke of shaft Z (mm) 1800 DRILLING STANKS:

- Max. depth (mm) 450 Deep hole drilling machines with internal high-pressure cooling

MACHINING WORKSHOP

LABORATORY

Highly qualified personnel and laboratory equipment allow us to perform all types of DESTRUCTIVE (DT) and NON-DESTRUCTIVE (NDT) tests required by all international standards. In addition, the main certifying bodies guarantee the quality of our products and our management.

DESTRUCTIVE TESTING (DT):

- Tensile and hot tensile tests at temperatures up to 600 C

- Impact strength tests at temperatures down to -196 C

- Hardness test (HRB, HRC, HB, HV)

- Drop Weight Test (Pellini)

- CTOD test

NON-DESTRUCTIVE TESTING (NDT):

- Ultrasonic Testing (UT)

- Magnetic Particle Test (MT)

- Paint Test (PT)

- Visual inspection (VT)

- Positive Material Inspection (PMI)

- Ferritic Content (Feritscope)

METALLOGRAPHICAL AND CORROSION TESTING:

- Macrographs

- Micrographs

- Corrosion Tests (HIC & SSC Test, …)

- Determination of ferrite grade

DESTRUCTIVE TESTING (DT):

- Tensile and hot tensile tests at temperatures up to 600 C

- Impact strength tests at temperatures down to -196 C

- Hardness test (HRB, HRC, HB, HV)

- Drop Weight Test (Pellini)

- CTOD test

NON-DESTRUCTIVE TESTING (NDT):

- Ultrasonic Testing (UT)

- Magnetic Particle Test (MT)

- Paint Test (PT)

- Visual inspection (VT)

- Positive Material Inspection (PMI)

- Ferritic Content (Feritscope)

METALLOGRAPHICAL AND CORROSION TESTING:

- Macrographs

- Micrographs

- Corrosion Tests (HIC & SSC Test, …)

- Determination of ferrite grade

SPECIAL EQUIPMENT

FREQUENTLY PRODUCED ITEMS:

- Oversized rolls and piercing (up to 8m).

- Roll handling and cutting lines

- High precision welding

- Lifting and turning equipment used for the manufacture of chassis, frames and heavy transportation components

- Truck carts for feeding and retrieving heavy and medium-heavy dies

-The shop produces unique products under NDA for such companies as Texaco (Chevron corporation), American Turbine (General Electric).

- Oversized rolls and piercing (up to 8m).

- Roll handling and cutting lines

- High precision welding

- Lifting and turning equipment used for the manufacture of chassis, frames and heavy transportation components

- Truck carts for feeding and retrieving heavy and medium-heavy dies

-The shop produces unique products under NDA for such companies as Texaco (Chevron corporation), American Turbine (General Electric).

TECHNICAL CAPABILITIES:

-Our equipment allows us to make holes up to 2000 mm deep in heavy metal products.

-We manufacture spare parts for continuous casting machines - such as molds

-The precision of our milling equipment allows us to machine holes of complex geometry with an accuracy of 0.1 mm

-Milling machines allow us to machine work surfaces up to 10400mm*3000mm*1500mm

-Electrical discharge machining allows us to obtain complex shapes that are difficult or impossible to obtain by traditional cutting methods.

-Our equipment allows us to make holes up to 2000 mm deep in heavy metal products.

-We manufacture spare parts for continuous casting machines - such as molds

-The precision of our milling equipment allows us to machine holes of complex geometry with an accuracy of 0.1 mm

-Milling machines allow us to machine work surfaces up to 10400mm*3000mm*1500mm

-Electrical discharge machining allows us to obtain complex shapes that are difficult or impossible to obtain by traditional cutting methods.

CNC MILLING MACHINES:

- ANAIAK HVM 7000: Work surface 5800 x 2500 x 1500 with a

rotary table 2000 x 2000.

- CORREA L30/74: Working surface 7400 x 1200 x 1500

- CORREA A25/50: Working surface 5000 x 1200 x 1500 (4th axis)

- ZAYER KF-4000: Working surface 4000 x 1200 x 1000

- CORREA A25/40: Working surface 4000 x 1000 x 1000 (4th axis)

- ZAYER KF-2500: Working surface 2500 x 1200 x 1000

- CORREA CF-22/25 PLUS: Working surface 2500 x 800 x 800

- CORREA CF-22/25: Working surface 2500 x 800 x 800

- ANAIAK HVM 7000: Work surface 5800 x 2500 x 1500 with a

rotary table 2000 x 2000.

- CORREA L30/74: Working surface 7400 x 1200 x 1500

- CORREA A25/50: Working surface 5000 x 1200 x 1500 (4th axis)

- ZAYER KF-4000: Working surface 4000 x 1200 x 1000

- CORREA A25/40: Working surface 4000 x 1000 x 1000 (4th axis)

- ZAYER KF-2500: Working surface 2500 x 1200 x 1000

- CORREA CF-22/25 PLUS: Working surface 2500 x 800 x 800

- CORREA CF-22/25: Working surface 2500 x 800 x 800

PIERCING MACHINE:

- SACEM: Working surface 3000 x 3000 x 2500 with deep drill bit

-FAMAS up to Ø29 x 1600

- SACEM: Working surface 3000 x 3000 x 2500 with deep drill bit

-FAMAS up to Ø29 x 1600

LATHES:

- GURUTZPE GL13.10.8: Ø900 x 8000

- AMUTIO HB 810: Ø810 x 5000

- AMUTIO HB 810: Ø810 x 2000

- AMUTIO HB 725: Ø725 x 4000

- AMUTIO HB 575: Ø575 x 1500

- AMUTIO HB 500: Ø500 x 1000

- GURUTZPE GL13.10.8: Ø900 x 8000

- AMUTIO HB 810: Ø810 x 5000

- AMUTIO HB 810: Ø810 x 2000

- AMUTIO HB 725: Ø725 x 4000

- AMUTIO HB 575: Ø575 x 1500

- AMUTIO HB 500: Ø500 x 1000

PRESSES

- Hydraulic press 100 tn

- Point press LOIRE 300 tn

- Hydraulic press 100 tn

- Point press LOIRE 300 tn

SAWS

-Automatic saw Uniz, Sabi

-Automatic saw Uniz, Sabi

3D SCANNER

GOM Atos III Scsn - portable

TRIMEK T-41-L - 2500*1500*1500

GOM Atos III Scsn - portable

TRIMEK T-41-L - 2500*1500*1500

ELECTROEROSION

NANX-7 2.300 x 1.500 x 700 mm 10 electrode changing system

NANX-7 2.300 x 1.500 x 700 mm 10 electrode changing system

CRANE CAPACITIES:

one-time lifting of products weighing up to 100 tons

one-time lifting of products weighing up to 100 tons

DEEP DRILLING

-MSA MF 1750 B evo (CN Heidenhain TNC 640) Working surface 2.000x2.200 (40 tons) (holes from 5-50mm, depth 2000 mm)

-Famas up to 32mm depth 1700 mm

-MSA MF 1750 B evo (CN Heidenhain TNC 640) Working surface 2.000x2.200 (40 tons) (holes from 5-50mm, depth 2000 mm)

-Famas up to 32mm depth 1700 mm

LABORATORY

outocumpu certification

outocumpu certification

ASSEMBLY SHOP:

- Tangential grinding machine L-1000.

- ERLO TCA-50: Drill - Roscamat up to M24: Automatic threading machine

- Tangential grinding machine L-1000.

- ERLO TCA-50: Drill - Roscamat up to M24: Automatic threading machine

Each DATUM TREE mechanical engineering project is formed based on the technical requirements of the customer.

Our company can develop Technical design documentation and Work design documentation from the scratch according to GOST and EN norms and standards.

The production capacities described above make it possible to assemble complex large-size equipment from high quality raw materials, using modern, up-to-date technologies.

For unique projects, complex, non-standard equipment DATUM TREE can form a first-class team of highly specialized specialists.

Our work begins with an audit and verification of all certificates and qualifications.

In agreement with the customer, DATUM TREE can engage a third party to externally audit processes and equipment during production stage.

Our company can develop Technical design documentation and Work design documentation from the scratch according to GOST and EN norms and standards.

The production capacities described above make it possible to assemble complex large-size equipment from high quality raw materials, using modern, up-to-date technologies.

For unique projects, complex, non-standard equipment DATUM TREE can form a first-class team of highly specialized specialists.

Our work begins with an audit and verification of all certificates and qualifications.

In agreement with the customer, DATUM TREE can engage a third party to externally audit processes and equipment during production stage.

MECHANICAL ENGINEERING

HEAT EXCHANGERS

PUMPS

VALVES

CONTAMINATED AND RADIOACTIVE WASTE STORAGE TANKS

BLADE SETS AND SPARE PARTS FOR TURBINES

FREQUENTLY PRODUCED

EQUIPMENT

EQUIPMENT